Niagara Systems, LLC

Niagara Systems, LLCRequest A Quote

Mentor, OH | 440-259-2500https://niagarasystemsllc.com/

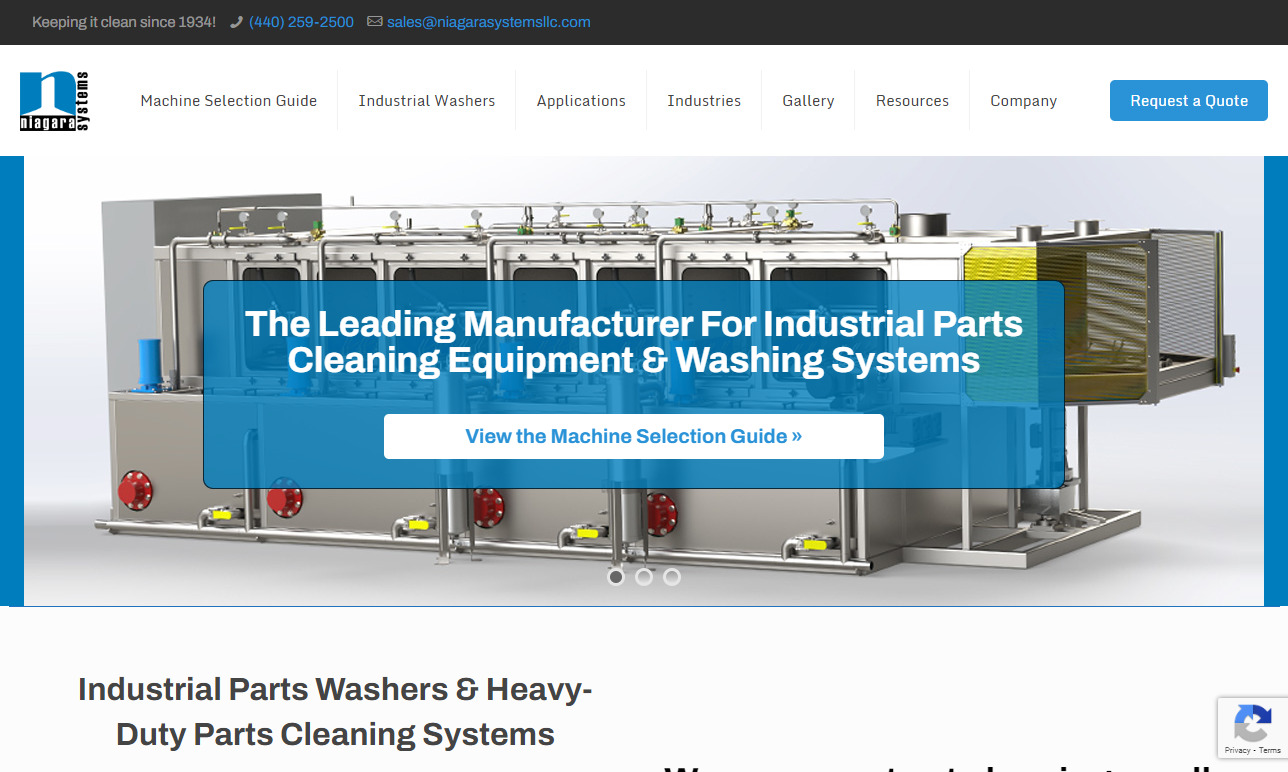

For over 80 years, Niagara Systems has excelled in building reliable automated washing and drying systems that have outshone the competition. We have experience providing these washing and drying systems for a multitude of industries, ranging from automotive to fish processing to musical instruments. Many components require critical, thorough cleaning in order to properly function. Fortunately, you can count on Niagara Systems’ machines to clean every item uniformly--ensuring a reduced cost of energy and labor, and the safety of the overall product. Our machines can also successfully remove debris and buildup from the most delicate products, such as light bulbs, crystal and china, or fluorescent tubes. In addition to cleaning equipment, we offer dependable industrial drying and curing ovens . They are equipped to handle the most sensitive materials, and are equipped with user-friendly temperature controls to ensure that it dries and cures the desired product safely. Our equipment is available in standard configurations, but if your application requires a custom system, our dedicated team of engineers will accept the challenge. They have the training and the expertise to assist our customers in every stage of the production planning process. Applications for which we have experience developing custom industrial washers include solar panels, computer screens, and nuclear fuel rods. Finally, after the system has been developed and installed, our team will assist you in operator training, data management and reporting, and acceptance testing that ensures that your system continues to run smoothly, and that you have the knowledge to properly operate it. Whether your application is in need of a simple dip washer, or a more complex multi-stage industrial washing system, Niagara Systems will provide the equipment you need and the services to help you maintain it.

Deburring Machinery

Deburring Machinery Industrial Parts Washers

Industrial Parts Washers Sandblast Equipment

Sandblast Equipment Ultrasonic Cleaners

Ultrasonic Cleaners Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services